Notoriously fiendish for excessive over-packaging, Japan swaddles everything in clear plastic, from individual bananas to wet umbrellas and tea bags, reportedly producing the second-highest annual plastic waste per capita after the US.

Look past plastic, however, and a wave of innovation is occurring. Companies and makers across the country are finding ways to repurpose discarded materials into new objects, spanning everything from chopsticks to indigo dye, as ideas of sustainability gain traction. Here are three examples that show how one person’s trash can truly become another’s treasure.

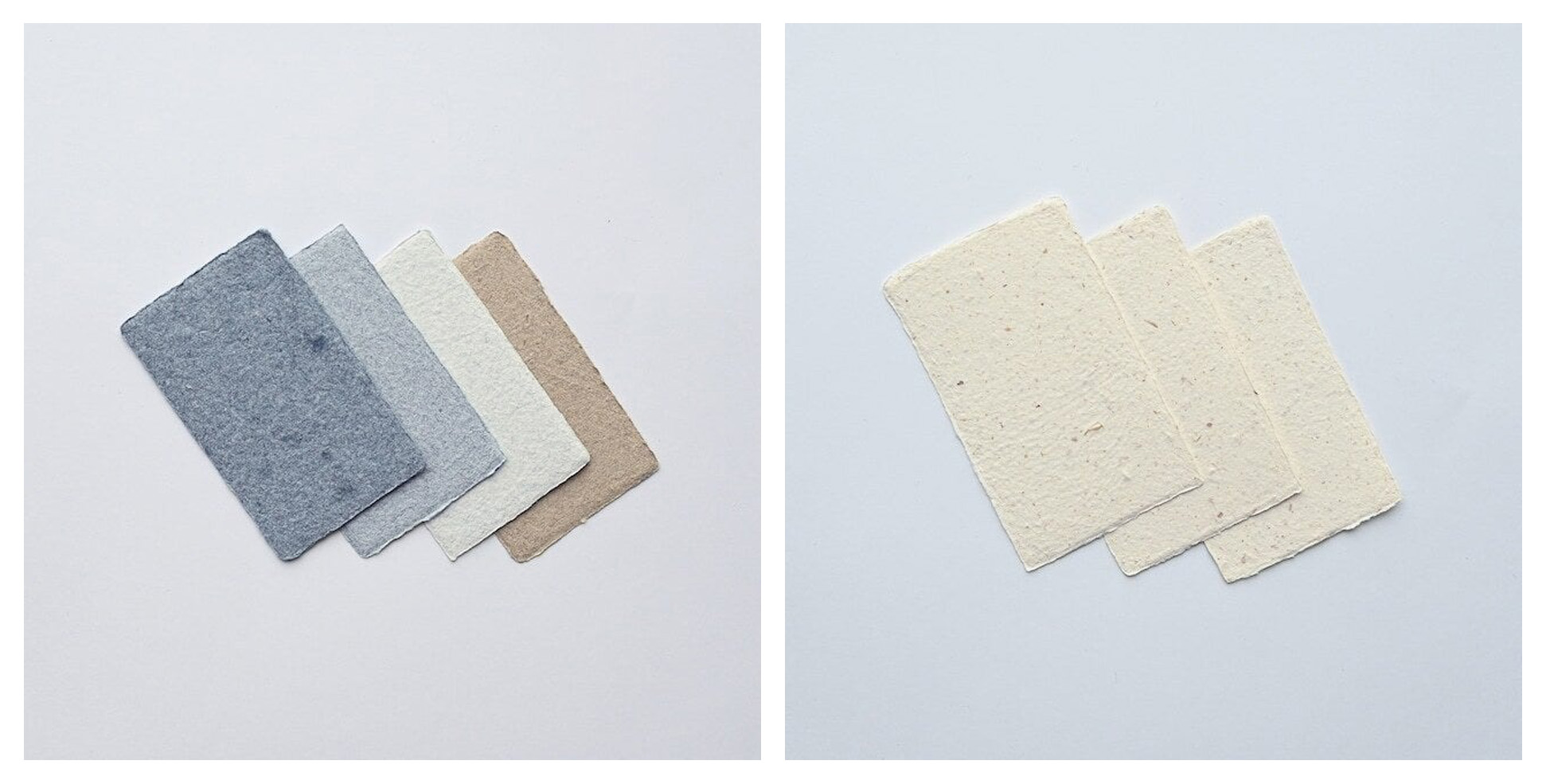

Meguru Tesukigami: Making Paper From Miso Paste, Denim and Furniture Waste

Meguru Tesukigami (Meguru Handmade Paper) hopes to “leave a better future for the next generation.” Started in 2022 by Kotobuki Printing Co. in Fuchi city, Hiroshima, this project has worked with local manufacturers to transform their waste products into paper, via environmentally friendly methods. The results are a range of beautiful new washi paper varieties blended with the fibers in denim, miso and wood — byproducts from some of the biggest industries in Fuchi.

The positive impact of this project doesn’t stop there, however. Keen to empower the local community, the workshop is staffed by residents with disabilities and offers its employees consistent and suitable work which is tailored to individual skill sets and interests. As the Senior Managing Director Masanori Muneto explains, the project aims to “contribute to the effective use of limited local resources, and to solving the problem of wage disparity for those with disabilities.”

Developing these fibrous mixes was no easy process, however, with days spent prototyping to achieve the right mix without the paper becoming too crumbly or felt-like, depending on the properties of the added fibers. The papers created from this process can be seen as a material celebration of the city itself: showcasing and embodying local manufacturing, traditional craft knowledge, innovation and community.

For more information, visit https://meguru-tesukigami.com/

TerrUp: Turning Discarded Chopstick Into Tables

Japan uses approximately 15 billion disposable wooden chopsticks each year. Around 10.7 billion of these are made from cypress wood and can be recycled into paper or tissues, but the remaining 4.3 billion are imported bamboo from overseas, and not so easily reused due to bamboo’s strong fibers, so they’re typically discarded. Realizing this, Yuichi Murakami founded TerrUp: a company turning used bamboo chopsticks into furniture pieces.

Murakami explains that he founded TerrUp after feeling a deep sense of mottainai (wastefulness) at a restaurant where he witnessed many chopsticks being thrown away after a banquet. “It seems a shame to throw away a chopstick that came all the way from China after just a few hours,” he says.

What emerged was the “Takezen Table,” a sturdy desk with an intricately patterned wooden surface and thick iron legs. Built to last, the table-top is produced by tightly arranging chopstick wood into bespoke large metal trays over which a resin is poured, before being placed in an industrial oven to set.

Murakami says it came to fruition after much trial and error: “If the oven time is too short, the resin won’t harden when pressed,” he adds. “If left in the oven for too long, the chopsticks will over-harden and become difficult to work with.”

When first setting up, TerrUp found collecting the discarded chopsticks difficult. However, the company now works with chain restaurants on a corporate scale and plans to release a range of different items in the future to recycle even more of Japan’s chopstick waste.

For more information, visit https://terrup.jp/en

Utena: Squeezing Yuzu Seeds Into Haircare

Founded in 1927, Utena Co. Ltd is a cosmetics company with a long history and a drive for innovation. This was evidenced in 1953 when it released Japan’s first face cream catered to men. This appetite for innovation continued when the company learned that despite yuzu being a powerful source of vitamins and antioxidants, its seeds are typically disposed of. Setting out to create a product that would find a use for these seeds, Utena created the Yuzu-Yu line of cosmetics (hair oil and hair mist).

Yuzu-Yu began when Utena approached the growers of Kitagawa village in Kochi, to buy their unused seeds. Despite being one of Japan’s largest yuzu producing areas, in recent years Kitagawa has faced the challenges of an aging farming community and a declining local population, so they welcomed this new opportunity for collaboration. Utena eventually refined a process of drying the seeds while retaining their nutrients, resulting in a product that can tackle damage with a glossy shine and sweet scent.

At the time of writing, the company has reportedly reused 100 million seeds and counting, winning awards for its ethos and planet-friendly packaging along the way.

Utena’s focus on sustainability extends to the Yuzu-Yu product packaging, with the oil and mist sold in 90% recycled brown glass and biomass PET bottles, and re-fill options made using botanical ink printing. The company received the Jury Award at the 2022 Sustainable Cosmetics Award, and can be found in drugstores across the country.

For more information, visit https://www.utena.co.jp/yuzu-yu/